..does not involve string at all.

As usual with miniature versions of craftsman made items, the smaller you go, the trickier it gets and the first thing you have to make are the tools to do the job.

Full size children’s dolls made of whatever hard material, where the doll is in similar size and proportions to a real human baby, are not too difficult to put together. Thick round elastic is threaded through the neck of the doll and can be caught by pushing a tool called a stringing hook, which is a metal hook on an arm a few inches long, into the body cavity and pulled out of the arm hole. The stringer can look through the arm hole to see where the elastic is in the body. The elastic is then threaded though a metal loop embedded into the top of the arm and back into the hollow body of the doll. The stringer can then peer through the leg hole, insert the stringing hook and catch the elastic to thread it through the loop on the leg. In this way, working round the body, the limbs are attached. When both ends of the elastic are protruding from the neck, they can be knotted through a stringing hook on the doll’s neck and pushed back into the body cavity, or into a neck hole on the head and thence out of a hole on the top of the head. One elastic will have a bead threaded on to prevent the elastic popping out of the hole, the ends are tied and the top head hole closed with a pate made of cork or card, and the wig is stuck on top.

Miniaturise all of that and nothing is simple. If very few people in the world are making fourteen part dolls under three inches, it’s because the main ingredient required is endless patience.

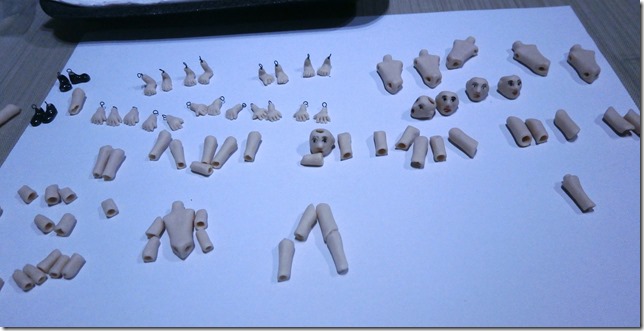

Here are all the parts poured, fired, grit scrubbed and ready to make fourteen part dolls, two and three quarter inches tall. It is the first time I have had a go. I made the moulds some years ago before everything happened. You can see how they all fit together in theory. In the top right of the picture are the bodies, top left are the feet and hands. I make the tiny loops to embed into the hands and feet from thin wire that will not melt in the high temperatures in the kiln. The twisted ends of the stringing loops need to be far enough apart to grab the porcelain molecules as they shrink in the kiln but not so far apart that this happens.

As you can see the wire has burst out of the wrist and the ankle in the kiln, so this hand and foot are unusable. You may be wondering why I cannot do better than that.

This is the reason –

the size of the hands and feet, which, of course, are appropriate for the size of doll. This, incidentally, is another unusable hand. I poured nine dolls, which is to say 14X9, or 126 doll parts. In the end I got two dolls out of it all.

Another reason is this, a blocked leg. When you are pouring legs this tiny they can be blocked with clay instead of hollow.

This is how it should look.

I could not have made dolls this small before the invention of resin elastic. Previously dolls were strung with round hat elastic, the smallest version of which was Japanese hat elastic. The elastic to string the lower leg has to go once through the leg hole, round the stringing hole in the foot and back up the same leg hole again. There was not a round, covered elastic made that could fit two lengths side by side in that hole, but half millimetre thick resin elastic does the job.

The other difficulty is kiln shrinkage. Doll parts placed nearer to the heating elements in the kiln can shrink more than those in the centre of the shelf so you get a result like this.

Additionally, the foot on the left has more ankle. In your hand, the tiny porcelain pieces don’t look much different but in twenty fourth scale, millimetres matter massively and add up to a doll with one long leg, or, possibly, a doll with one short leg. Additionally, ankles millimetres thicker will not fit into the hole on the bottom of the leg (this is true for every one of thirteen joints.) Also when making the holes in the poured porcelain, they have to be evenly spaced. A hole near the top of the shoulder on one side of the torso and a hole millimetres lower on the other side will make the doll look as if it is shrugging at least. Holes in the top of the arms must come out of the side for the arm to lower to the body, or the doll will always have a raised arm. Much of this is not, sadly, apparent until the porcelain is fired.

Hours are spent sorting through all the parts to find exactly matching pairs with perfect holes, flat ends, no wires showing and all the rest of it.

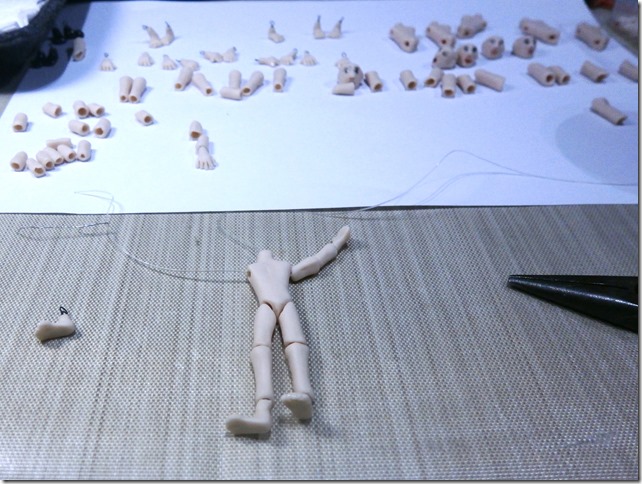

Actual stringing is a matter of extreme patience and tools made with very small bits of wire. Very occasionally elastic will go into the depths of a body and curve, on its own, out of the leg hole, or the arm hole or wherever it is destined to go next. Much more often, after half an hour of trying, I make a temporary stringing hook to achieve this.

This is the bit that you need three hands for, or, ideally, not to sneeze just when you have got the end coming out of the hole.

So now you think you have got it sorted, that you have gone through all one hundred and twenty six pieces and found the matches that will make a body.

Which is when you find out that someone has made the hole in the top of the head smaller than the neck hole, which means that, supposing you can find a bead small enough to go on to the elastic and through the top of the head, it will immediately fall out of the neck, so that head is another waster.

We know of the existence of some of the early eighteenth century porcelain factories by their wasters. Items that went wrong in the kiln, in any of the processes, were dumped and gradually buried in accumulated rubbish, only being found when a new underground rail line was being excavated, for example. It’s comforting to know that I am not the only one struggling with an unforgiving medium.

Sometimes, however, the stars align and the patience pays off.

And you get two dolls out of one hundred and twenty six bits. The leftovers go into a little plastic drawer.

You should just see how many drawers I have. (In a cabinet up the wall, taller than I am.)

If, in a hundred years, people find the dolls and ask how anybody managed to do this, you’ll be able to tell them it was done with patience to make collectors happy. Which is exactly the same as it was in the eighteenth century.

~~~~~~~~~~~~~~~~~~~~~~~~~~